Your winery cleaning needs don’t require multiple products, machines and accessories. There are systems that have tools and attachments that will clean tanks, bottling lines, tanks and other winery equipment with just a single unit.

One of the top cleaning methods for not just providing deep clean but also sanitising winery equipment is high temperature steam technology. Here are key ways steam not just cleans but protects wine quality.

Learn three ways on how to deep clean wine barrels and equipment

High temperature steam

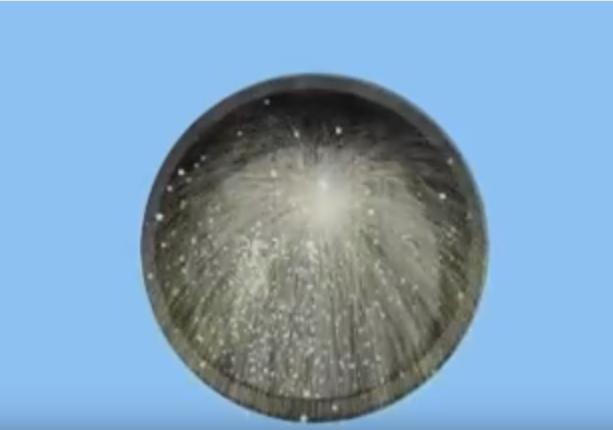

The high temperature competent of steam vapour allows for steam to get into the pores of the barrel and extract old wine, dirty water and other volatiles.

Unlike washing only systems, steam penetrates through the surface and gets into nooks and crannies that traditional systems can’t find difficult.

Dry steam

The dry component of steam vapour rehydrates barrels and allows for the use of the barrel to be extended by up to 25 per cent. This keeps winery costs down and allows winemakers to get the most out of their barrels.

Kills brettanomyces

High temperature steam at +165 degrees Celsius is seen in hospital environments to kill aggressive pathogens and bacteria. With brettanomyces being bacteria that are a threat to the winemaking process, using a high temperature steam treatment on barrels prior to storage and use will safeguard wine quality.