Treating Wine Barrels

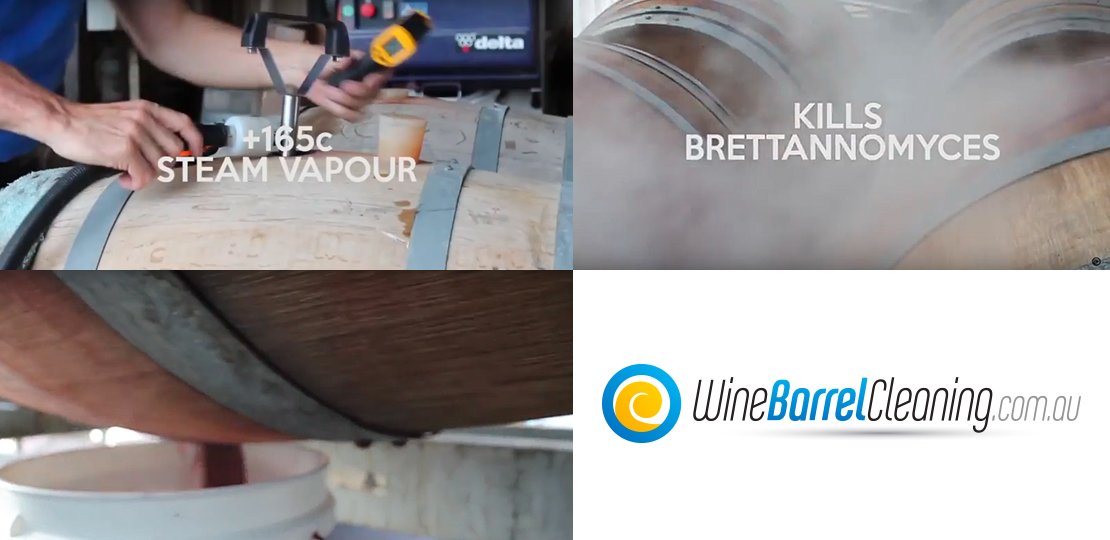

Wine Barrel Cleaning adopts best practice in winery barrel treatment and prolongs the life of barrels by up to 25% saving you thousands. Dry steam vapour cleaning technology is a powerful and natural way to clean any surface, without the use of chemicals. Steam vapour kills Brettanomyces yeasts, Lactobacillis and Pediococcus instantly. We have an impressive range of commercial wine barrel cleaning equipment and barrel handling machines to streamline your winery's workflow.

Quick Set Up

Distribute the steam vapour throughout all the areas of the barrel's interior.

Avoids moisture build up in the low spots of the barrel.

- Fast set-up, quick operation.

- A natural treatment guaranteed to work.

- Protect your barrel investment.

Banish Bretts

Sanitise wine barrels, with the added advantage of using a chemical-free process.

Keep barrels hygienic to prevent the buildup of tartrates and yeast.

- Remove Lactobacilius.

- Complete barrel interior treatment.

- The ideal maintenance for users.

Industrial Grade Fittings

Rugged industrial connectors attach the pressurised output hose to the bottling line.

Remove all impurities and contaminants- so the wine is not spoiled during bottling.

- Stainless steel fittings.

- Up to 6 bar steam pressure.

- Destroy bacteria and germs.

Maintenance of New Barrels During Storage

Treating barrels instantly is an essential process from the moment you take delivery. If you're not ready to use your barrels right away, they must be stored away from dampness or mould. The ideal conditions are around 13 degrees Celsius and humidity levels of between 65% and 75%. Observing and adhering to these guidelines is essential, to prevent or minimise shrinkage of the wood.

Treating New Barrels Before Use

Before using a new wine, the barrel must be swelled. Clean water is used, and the primary purpose is to swell all joints and croze, to prevent wine leak. Another reason for swelling a wine barrel is to tighten wood joints so that air does not enter the barrel and oxidise the wine. If joints are not swelled properly, there is a real risk of mould entering through the cracks, and spoiling the wine.

Treating and Maintaining Used Barrels

Used wine barrels over a season or more- need different management to new barrels. If the barrel is being emptied of wine and refilled immediately, all that's required is cleaning with one of our high-pressure wine barrel cleaning machines. These are available in a range of strengths and capacities to suit the workflow and barrel count of the winery.

Dry Steam Vapour as a Wine Barrel Cleaner - Nature's Sterilizer

Steam Vapour is an excellent all natural cleaner, ideally suited to wineries. It destroys all bacteria and leaving the barrel dry, ready for immediate use. Maintaining and treating wine barrels with high-temperature steam vapour instead of a water rinse, sterilises the barrel, and kills all traces of mould and bacteria.

Brettanomyces or "Brett" can impart a clinical or "first aid cupboard" taste to the wine, once contamination reaches an advanced state. Cleaning the barrel with steam vapour also destroys Lactobacillis and Pediococcus bacteria. Contamination by either of these two lactic acid bacteria can infuse the wine with the flavour of sour milk.

Save water, extend the life of used wine barrels, and prevent bacteria outbreak in all areas of the winery, by sanitising with the amazing cleaning properties of steam vapour. Arrange for a demonstration today and embrace the advantages of using Nature's very own cleaning agent, throughout your wine barrel treatment and maintenance program.

Contact us for more information about treating wine barrels